Tel: +86-371-86107816

Fax: +86-371-63797816

E-mail: info@tjcsteel.com

Add: Fortune Plaza, Zhengzhou, Henan, China

Skype: tjccarl

|

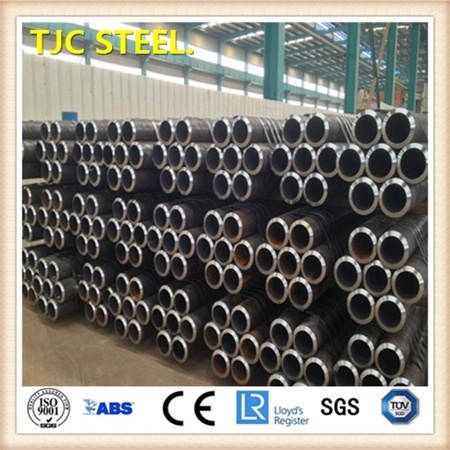

Product name : DIN17175 15Mo3 Heat-Resistant Seamless Steel Tubes

Item : 20247611847

|

| Details: |

The DIN17175 15Mo3 heat-resistant seamless steel tubes are renowned for their superior performance in high-temperature environments. This product, adhering to the stringent DIN17175 standard, offers a robust combination of chemical composition, mechanical properties, and heat treatment states, making it a preferred choice for various industrial applications.

Chemical Composition: The 15Mo3 grade of steel in these tubes is characterized by its unique chemical composition. It primarily consists of carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, and nickel, with precise percentages tailored to ensure optimal performance. The molybdenum content, specifically, contributes significantly to the alloy's heat resistance. Mechanical Properties: The mechanical properties of DIN17175 15Mo3 tubes are impressive. With an ultimate tensile strength ranging from 450 to 600 MPa and a yield strength of at least 270 MPa, these tubes can withstand significant stresses. Furthermore, their elongation rate of at least 20% ensures ductility and flexibility, crucial for applications involving thermal expansion and contraction. Heat Treatment States: The heat treatment states of these tubes are carefully controlled to enhance their performance. Common heat treatment methods include annealing, normalizing, and quenching and tempering. These processes optimize the microstructure of the steel, resulting in improved mechanical properties and resistance to corrosion and oxidation. Size Range: The DIN17175 15Mo3 tubes are available in a wide range of sizes. The outer diameter can vary from 6.35 to 114 millimeters, while the wall thickness ranges from 0.89 to 15 millimeters. This versatility allows for the tubes to be used in various applications, from small-scale piping systems to large-scale boilers. Impact Testing: Impact testing is a crucial step in ensuring the quality and reliability of DIN17175 15Mo3 tubes. These tests are performed to assess the material's ability to withstand sudden impacts or rapid loading, ensuring that it meets the stringent requirements for applications involving high-pressure and high-temperature conditions. Primary Applications: The DIN17175 15Mo3 heat-resistant seamless steel tubes find widespread applications in various industries. They are commonly used in boilers, power plants, and petrochemical plants, where they are exposed to high temperatures and pressures. Their excellent heat resistance and mechanical properties make them suitable for use in the heating surfaces, economizers, superheaters, and reheaters of boilers. TJC Steel Group Supply Cases: TJC Steel Group is a renowned supplier of DIN17175 15Mo3 heat-resistant seamless steel tubes. With a vast inventory and extensive experience in the steel industry, TJC provides customized solutions to meet the specific needs of its customers. Some of the notable supply cases include the provision of these tubes for large-scale boiler projects in power plants, where their superior performance has been highly appreciated. In conclusion, the DIN17175 15Mo3 heat-resistant seamless steel tubes are a reliable choice for applications requiring superior heat resistance and mechanical properties. Their unique chemical composition, mechanical properties, heat treatment states, and wide size range make them suitable for various industrial applications. With TJC Steel Group as a trusted supplier, customers can rest assured of receiving high-quality products and exceptional service. |

| Related Products : |

Copper Alloy Plate

Copper Alloy Plate

JIS G3445 Steel Pipe

JIS G3445 Steel Pipe