Tel: +86-371-86107816

Fax: +86-371-63797816

E-mail: info@tjcsteel.com

Add: Fortune Plaza, Zhengzhou, Henan, China

Skype: tjccarl

|

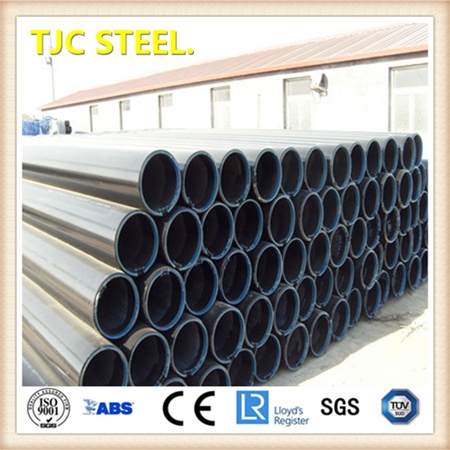

Product name : DIN17175 13CrMo44 Heat-Resistant Seamless Steel Tubes

Item : 2024761135

|

| Details: |

DIN17175 13CrMo44 heat-resistant seamless steel tubes are among the most sought-after materials in the industrial sector, owing to their superior chemical composition, mechanical properties, and heat-resistant capabilities. This article aims to provide a detailed overview of these tubes, highlighting their chemical composition, mechanical properties, heat treatment state, dimensional range, impact testing, major applications, and relevant supply cases from TJC Steel Group.

Chemical Composition The 13CrMo44 seamless steel tubes adhere strictly to the DIN17175 standard, ensuring a precise balance of chemical elements. The key components include carbon (C: 0.08-0.18%), silicon (Si: 0.10-0.35%), manganese (Mn: 0.4-1.0%), chromium (Cr: 0.70-1.10%), molybdenum (Mo: 0.40-0.60%), and copper (Cu: 0.30%). The addition of chromium and molybdenum enhances the corrosion resistance and heat resistance of the tubes, while the copper content contributes to their overall strength. Mechanical Properties The mechanical properties of 13CrMo44 seamless steel tubes are remarkable. They possess a tensile strength ranging from 440 to 590 MPa and a yield strength of at least 290 MPa. The minimum elongation percentage is 22%, indicating their excellent ductility. These properties ensure that the tubes can withstand high pressures and temperatures without deformation or failure. Heat Treatment State The 13CrMo44 seamless steel tubes are supplied in a normalized condition, with a heat treatment temperature ranging from 890°C to 950°C. This heat treatment process improves the toughness and strength of the material, making it more suitable for demanding applications. Dimensional Range The tubes are available in a wide range of dimensions to cater to different industrial needs. The outer diameters can vary depending on the specific requirements, while the wall thicknesses are optimized to ensure maximum strength and durability. Impact Testing To ensure the reliability and safety of the 13CrMo44 seamless steel tubes, impact testing is performed at various temperatures. These tests involve subjecting the tubes to sudden impacts to assess their ability to withstand shocks and impacts in real-world applications. Major Applications The 13CrMo44 seamless steel tubes find extensive applications in various industries, particularly in the manufacturing of boilers and pressure vessels. Their superior heat resistance and mechanical properties make them ideal for use in steam boilers, heat exchangers, superheaters, and reheaters. Additionally, they are also used in the chemical industry for manufacturing equipment that requires high resistance to corrosion and heat. TJC Steel Group Supply Cases TJC Steel Group, a leading supplier of industrial steel products, has a proven track record in supplying DIN17175 13CrMo44 heat-resistant seamless steel tubes to various industries. Our tubes have been successfully used in numerous projects, including the construction of power plants, chemical plants, and oil & gas refineries. Our expertise in material selection and quality assurance ensures that our clients receive the best possible products for their specific needs. In conclusion, DIN17175 13CrMo44 heat-resistant seamless steel tubes are an excellent choice for applications that require superior heat resistance and mechanical properties. Their precise chemical composition, optimized mechanical properties, and reliable performance have made them a trusted material in various industries. TJC Steel Group is proud to be a leading supplier of these tubes, offering competitive prices and exceptional customer service. |

| Related Products : |

Copper Alloy Plate

Copper Alloy Plate

JIS G3445 Steel Pipe

JIS G3445 Steel Pipe