Tel: +86-371-86107816

Fax: +86-371-63797816

E-mail: info@tjcsteel.com

Add: Fortune Plaza, Zhengzhou, Henan, China

Skype: tjccarl

|

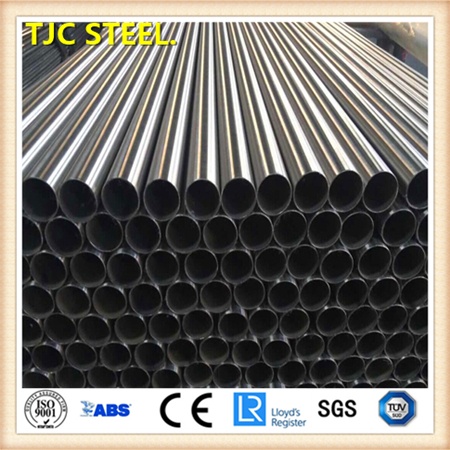

Product name : DIN17175 14MoV63 Heat-Resistant Seamless Steel Tube

Item : 20247611442

|

| Details: |

In the realm of high-temperature industrial applications, the DIN17175 14MoV63 heat-resistant seamless steel tube stands as a testament to its unwavering reliability and durability. Manufactured by TJC Steel Group, these tubes are specifically designed to handle the rigorous demands of elevated temperatures while maintaining exceptional performance.

Chemical Composition The 14MoV63 grade of steel is renowned for its balanced chemical composition, which includes precise percentages of Carbon (C), Silicon (Si), Manganese (Mn), Phosphorus (P), Sulphur (S), Chromium (Cr), Nickel (Ni), Copper (Cu), Molybdenum (Mo), Vanadium (V), and Aluminum (Al). This composition ensures superior mechanical properties and resistance to oxidation and corrosion at high temperatures. Mechanical Properties The mechanical properties of 14MoV63 steel tubes are truly remarkable. With a tensile strength ranging from 460 to 610 MPa and a yield point of at least 320 MPa, these tubes exhibit excellent strength and ductility. Furthermore, the elongation rate and impact absorption energy ensure that they can withstand sudden changes in temperature and pressure without failing. Heat Treatment Status To achieve the desired mechanical properties and microstructure, 14MoV63 steel tubes undergo various heat treatment processes such as cold drawing (BK), annealing (Annealing), stress-relief annealing (BKS), normalizing (Normalized), and bright annealing (NBK). These treatments enhance the toughness, ductility, and overall performance of the tubes. Dimensional Range The dimensional range of DIN17175 14MoV63 tubes is extensive, catering to various industrial applications. The tubes are available in outer diameters ranging from 6.35 to 114 millimeters and wall thicknesses varying from 0.89 to 15 millimeters. This versatility allows for customization to meet specific project requirements. Impact Testing To ensure the tubes' ability to withstand sudden impacts, impact testing is conducted on tubes with wall thicknesses greater than 16 millimeters. This testing verifies the tubes' resilience and durability in high-stress environments. Main Applications The DIN17175 14MoV63 heat-resistant seamless steel tubes find widespread applications in various industries. They are commonly used in automotive and bearing industries, machinery and construction, as well as in boilers, power stations, superheaters, heat exchangers, high-pressure oil pipelines, and petrochemical plants. The tubes' ability to withstand high temperatures and pressures makes them indispensable in these demanding applications. TJC Steel Group Supply Cases As a leading manufacturer and supplier of DIN17175 14MoV63 heat-resistant seamless steel tubes, TJC Steel Group has a robust portfolio of successful supply cases. From power generation plants to petrochemical complexes, TJC Steel Group has delivered high-quality tubes that have met and exceeded customer expectations. The company's commitment to quality, reliability, and customer satisfaction is evident in every tube it produces. In conclusion, the DIN17175 14MoV63 heat-resistant seamless steel tube is a dependable solution for high-temperature industrial applications. Its superior chemical composition, mechanical properties, and heat treatment processes ensure reliable performance and long-lasting durability. With TJC Steel Group as your trusted supplier, you can be assured of receiving the best-in-class tubes for your specific needs. |

| Related Products : |

Copper Alloy Plate

Copper Alloy Plate

JIS G3445 Steel Pipe

JIS G3445 Steel Pipe