Tel: +86-371-86107816

Fax: +86-371-63797816

E-mail: info@tjcsteel.com

Add: Fortune Plaza, Zhengzhou, Henan, China

Skype: tjccarl

|

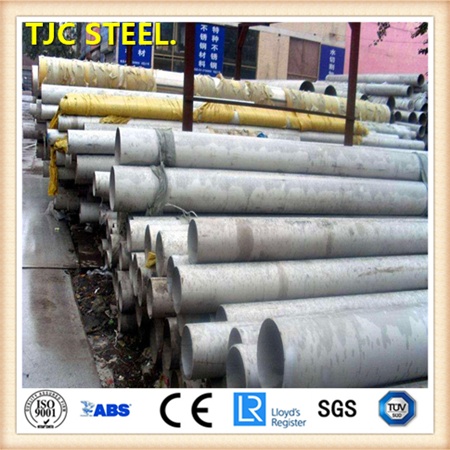

Product name : DIN 17175 19Mn5 Heat-Resistant Seamless Steel Tubes

Item : 202476105538

|

| Details: |

DIN 17175 19Mn5 heat-resistant seamless steel tubes are precision-engineered to meet the stringent demands of various industrial applications. These tubes are manufactured from 19Mn5 steel, a grade known for its excellent heat resistance, mechanical properties, and welding capabilities. Here, we delve deeper into the key aspects of these tubes to provide a comprehensive product introduction.

Chemical Composition The 19Mn5 steel grade used in the production of these tubes boasts a well-balanced chemical composition. The primary elements include carbon (C) ranging from 0.17% to 0.22%, silicon (Si) between 0.30% and 0.60%, and manganese (Mn) with a content of 1.00% to 1.30%. Additionally, the phosphorus (P) and sulfur (S) content are limited to 0.045% or less, ensuring superior corrosion resistance. The chromium (Cr) content is kept below 0.30%, further enhancing the heat resistance of the tubes. Mechanical Properties The mechanical properties of DIN 17175 19Mn5 tubes are outstanding. These tubes exhibit high tensile strengths ranging from 510 MPa to 610 MPa, with a minimum yield strength of 315 MPa. The elongation at break, or ductility, is typically above 20%, ensuring good flexibility and formability. Furthermore, the tubes demonstrate excellent impact resistance, with impact energy values ranging from 34 Joules and above. Heat Treatment The heat treatment process plays a crucial role in enhancing the properties of DIN 17175 19Mn5 tubes. The tubes undergo normalization at 880°C to 910°C, which improves their internal structure and mechanical properties. Additionally, stress relief annealing may be performed at 550°C to 620°C to reduce residual stresses, resulting in improved dimensional stability and resistance to deformation. Dimensional Range DIN 17175 19Mn5 tubes are available in a wide range of sizes to cater to diverse applications. The outer diameters range from 6.35 mm to 114 mm, while the wall thicknesses vary from 0.89 mm to 15 mm. This versatility allows for flexibility in design and engineering, ensuring optimal performance in various settings. Impact Testing Impact testing is a crucial step in the quality assurance process for DIN 17175 19Mn5 tubes. These tests assess the tubes' ability to withstand sudden impacts, providing valuable insights into their toughness and durability. The impact energy values achieved during these tests are indicative of the tubes' resistance to cracking or breaking under sudden loads. Applications DIN 17175 19Mn5 tubes find widespread applications in various industries. Their excellent heat resistance and mechanical properties make them suitable for use in boilers, superheaters, heat exchangers, and other equipment operating at high temperatures. Additionally, their corrosion resistance ensures durability in environments with harsh chemicals or oxidizing agents. Supply Case Study: TJC Steel Group TJC Steel Group is a leading supplier of DIN 17175 19Mn5 heat-resistant seamless steel tubes. We have a robust supply chain and advanced manufacturing capabilities, enabling us to provide high-quality tubes in various sizes and specifications. Our tubes have been successfully used in numerous projects across various industries, including power generation, petrochemicals, and oil and gas. Our customers appreciate our commitment to quality, reliability, and timely delivery, making TJC Steel Group their preferred choice for DIN 17175 19Mn5 tubes. |

| Related Products : |

Copper Alloy Plate

Copper Alloy Plate

JIS G3445 Steel Pipe

JIS G3445 Steel Pipe