Tel: +86-371-86107816

Fax: +86-371-63797816

E-mail: info@tjcsteel.com

Add: Fortune Plaza, Zhengzhou, Henan, China

Skype: tjccarl

|

Product name : A387Gr911CL2/A387 Grade 911 Class 2 Chromium-Molybdenum Alloy Steel Plates

Item : 2024811173359

|

| Details: |

Introduction

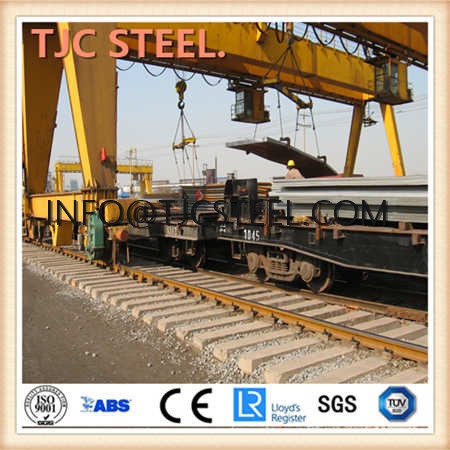

The A387Gr911CL2/A387 Grade 911 Class 2 chromium-molybdenum alloy steel plates are premium industrial materials specifically designed for use in pressure vessels and boilers under high temperature and pressure conditions. Manufactured to strict specifications, these plates exhibit exceptional properties that make them ideal for demanding applications in various sectors. In this article, we will delve into the detailed chemical composition, mechanical properties, heat treatment status, size range, impact testing, primary applications, and supply cases by TJC Steel Group. Chemical Composition The A387Gr911CL2/A387 Grade 911 Class 2 plates are composed of a unique blend of chemical elements, including carbon (C), manganese (Mn), silicon (Si), phosphorus (P), sulfur (S), chromium (Cr), and molybdenum (Mo). The precise ranges of these elements ensure optimal performance in harsh environments. The typical chemical composition ranges are as follows: - Carbon (C): 0.05% to 0.17% - Manganese (Mn): 0.40% to 0.65% - Silicon (Si): 0.15% to 0.40% - Phosphorus (P): ≤0.025% - Sulfur (S): ≤0.035% - Chromium (Cr): 0.80% to 1.15% - Molybdenum (Mo): 0.45% to 0.60% Mechanical Properties The mechanical properties of A387Gr911CL2/A387 Grade 911 Class 2 plates are outstanding, making them suitable for applications requiring high strength and ductility. Key mechanical properties include: - Tensile Strength (MPa): 380-550 MPa - Yield Strength (MPa): ≥230 MPa - Elongation at 200mm (%): ≥18% - Elongation at 50mm (%): ≥22% These properties ensure that the plates can withstand significant stresses and deformations without failing, even under extreme operating conditions. Heat Treatment Status To achieve the desired properties, A387Gr911CL2/A387 Grade 911 Class 2 plates undergo a rigorous heat treatment process. The plates are normalized at a temperature range of 1040-1080°C, followed by tempering at 730-800°C. This process ensures that the plates have optimal microstructure and properties for their intended applications. Size Range The A387Gr911CL2/A387 Grade 911 Class 2 plates are available in a wide range of sizes to meet various project requirements. Typical thicknesses range from 6mm to 70mm, with widths up to 2500mm and lengths up to 12000mm. Custom sizes can also be manufactured upon request. Impact Testing To ensure reliability in low-temperature environments, A387Gr911CL2/A387 Grade 911 Class 2 plates undergo rigorous impact testing. This testing evaluates the plates' ability to withstand sudden changes in temperature and load without fracturing. The specific impact test requirements vary depending on the application and customer specifications. Primary Applications The exceptional properties of A387Gr911CL2/A387 Grade 911 Class 2 plates make them suitable for a wide range of demanding applications, including: - Pressure vessels for petrochemical and oil refining industries - Boilers for power generation - High-temperature reactors and heat exchangers - Hydrogenation and reforming equipment in the chemical industry - Pipes and tubes for high-temperature fluid transport TJC Steel Group Supply Cases TJC Steel Group, as a leading supplier of premium steel products, has successfully delivered A387Gr911CL2/A387 Grade 911 Class 2 plates to numerous projects worldwide. Some notable supply cases include: - Power Generation: Supplying boiler plates for several large-scale power plants, ensuring reliable and efficient operation under high temperature and pressure conditions.

|

| Related Products : |

Copper Alloy Plate

Copper Alloy Plate

ASME SA285/ SA285M Pressure Vessel Steel

ASME SA285/ SA285M Pressure Vessel Steel